AccuNET - Controller

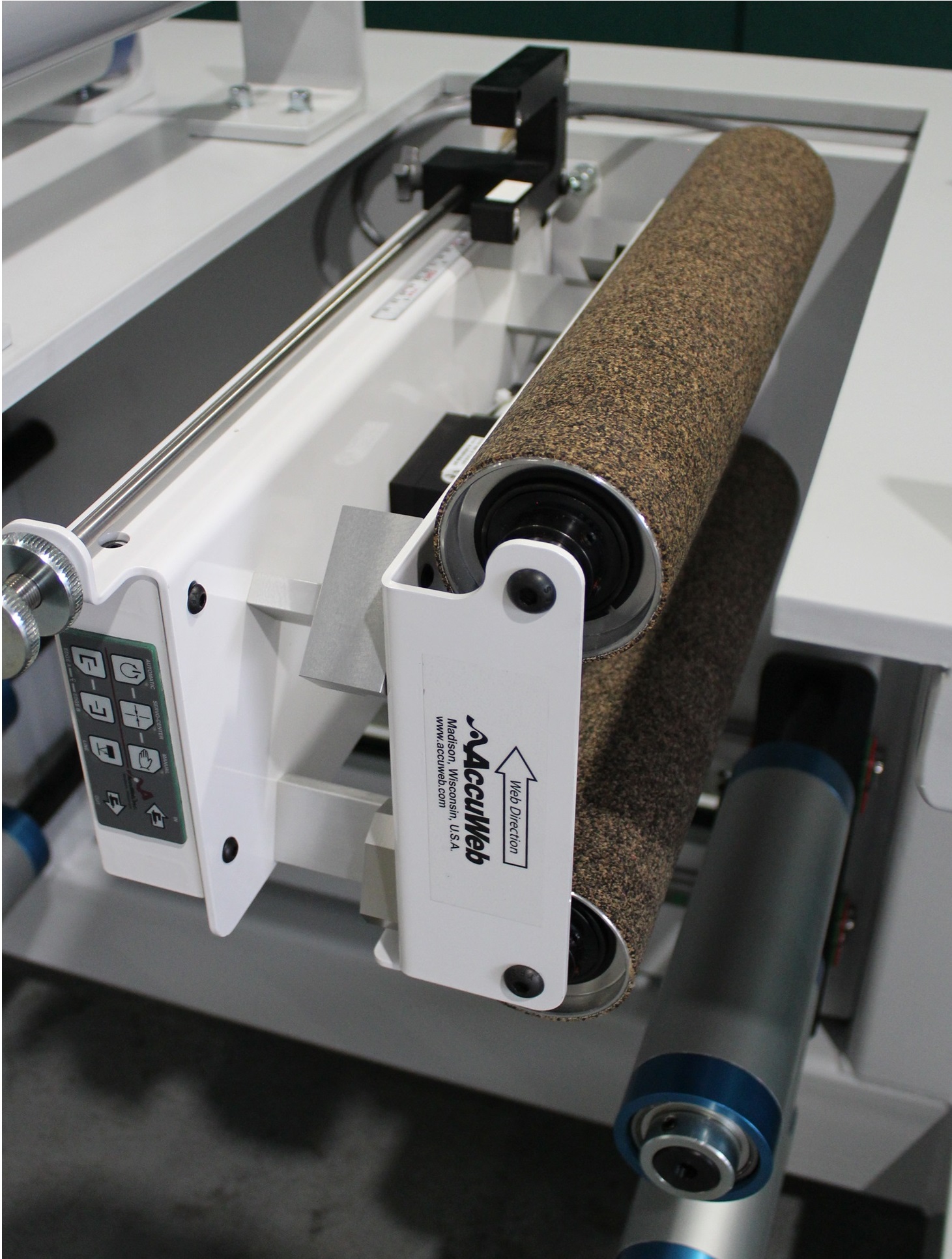

- Product Images:

- Images:

- Images:

- Product Intro:

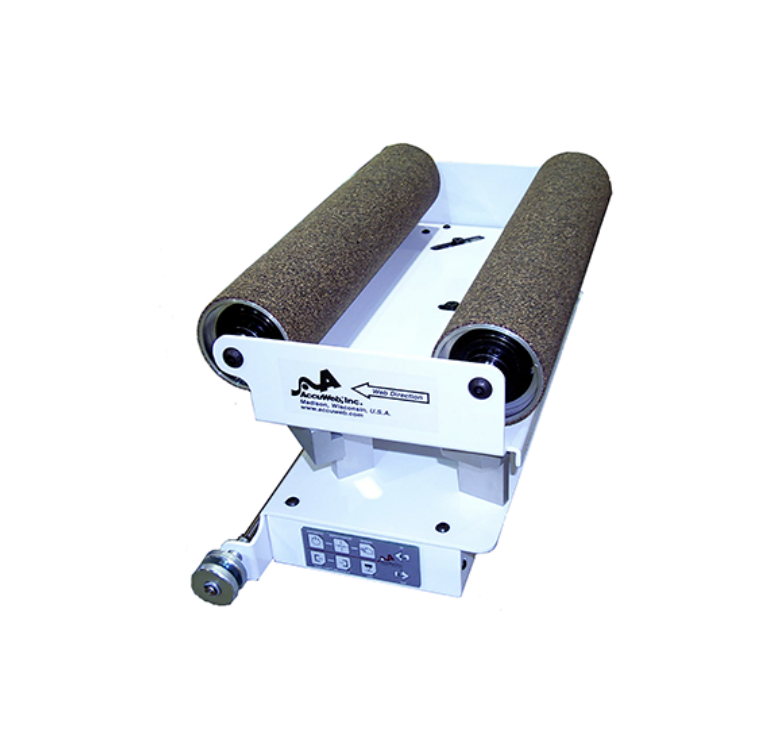

SUPERIOR SPEED & ADVANCED TECHNOLOGY IN A COMPACT WEB GUIDE CONTROLLER.

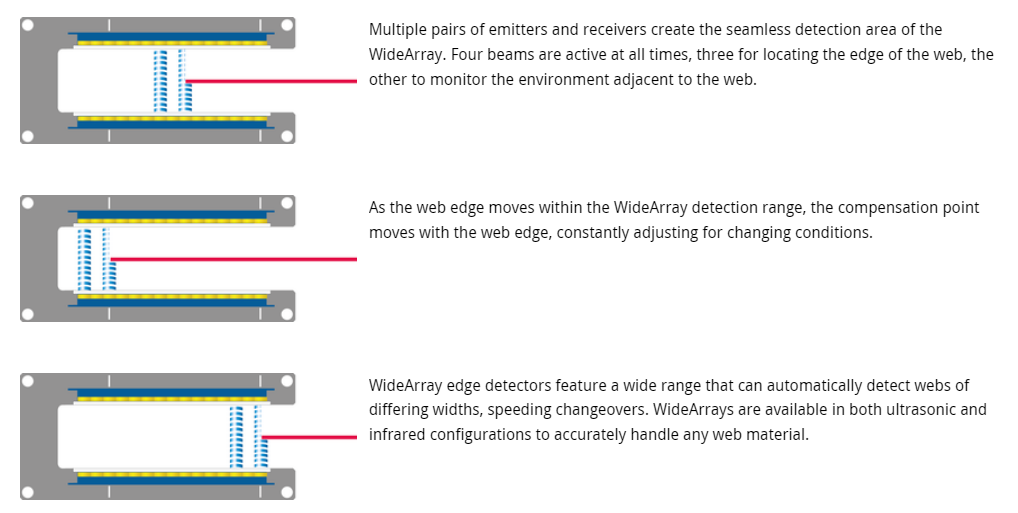

AccuWeb’s dynamically compensated WideArray™ and PointSource™ edge detectors as well as WideArray 2.0™ and CLS Pro 600. - Product Description:

24 V DC Operation - The AccuNET controller is easy to integrate into existing converting lines or control panels.

Symmetrical Edge Processing - Parralled processing with 2 PointSource or WideArray edge detectors.

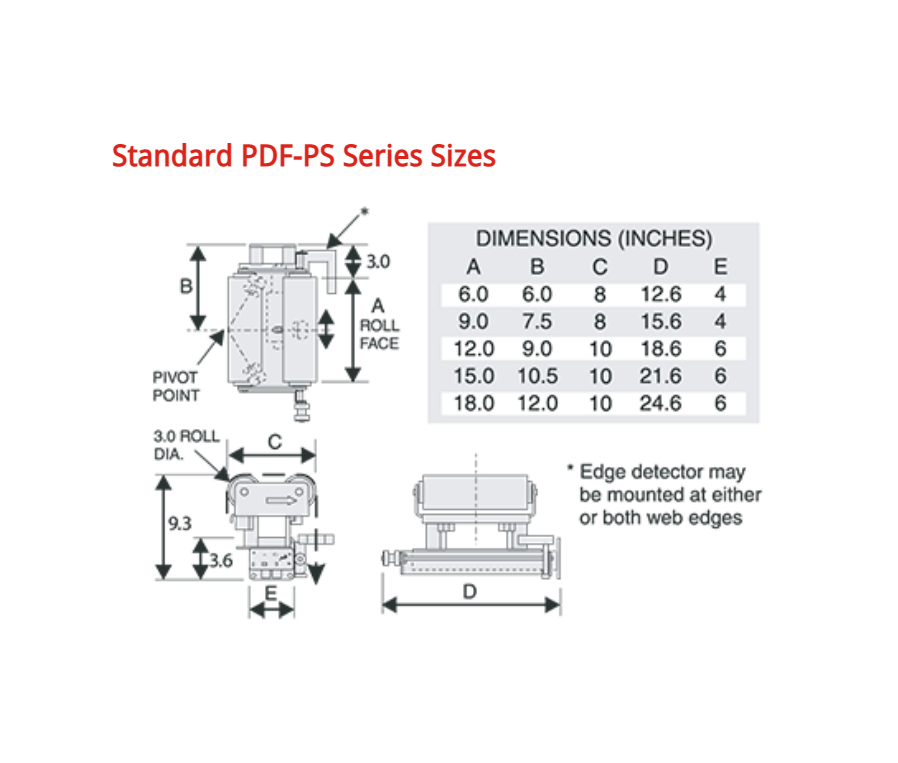

DualEdge™ Guiding – Capable of centerline guiding webs up to 18” wide using a single WideArray edge detector.

Backwards Compatibility - Compatible with all existing PointSource and WideArray edge detectors.

WideArray 2.0™ and CLS Pro Compatible - Seamless plug and play compatibility.

Faster Response - 32 Bit processing plus fast closed loop for better performance.

Built In Discrete I/O - Standard feature for easy integration.

Operator Friendly - Intuitive operator interface with 5" color touch screen.

Network Friendly - Integrated fieldbus easily interfaces with most popular fieldbus networks, including Ethernet IP, ProfiNET, EtherCAT and Modbus TCP.

Upgrade Friendly - Add new features and increased speed to older systems.