Controllers

Micro 4000Net - Controller

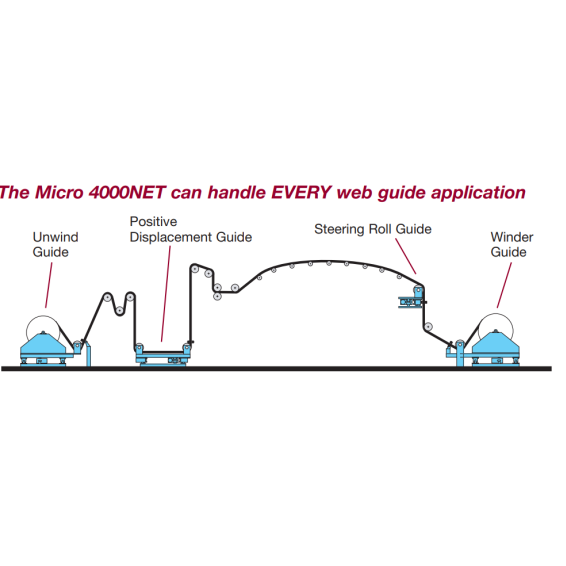

THE MICRO 4000NET IS DESIGNED TO HANDLE THE MOST DEMANDING WEB GUIDE APPLICATIONS.

The Micro 4000NET controller is the heart of the industry’s most advanced web guide system. It is designed to handle any application, perform in any environment, and guide all web materials. It offers outstanding flexibility by interfacing with existing customer networks and PLCs. The result is the ability to provide unmatched accuracy, consistency and reliability. It is compatible with all of AccuWeb’s dynamically compensated WideArray™ and standard edge detectors, AccuBeam® 3 line guide, and all linear actuators — all in one enclosure.

The Micro 4000NET uses distributed control technology to eliminate the installation hassles of long cable runs, expensive conduit and tedious wiring checkouts. Through the use of fieldbus communications via a small shielded cable, Micro 4000NET can send and receive web guide commands from a customer PLC or PC. A compact Micro 4000NET enclosure is mounted at each of the web guide locations and networked with one simple connection. This set-up uses shorter cables for edge detectors and linear actuator hook ups.

-

Compatible with CANopen™, ControlNet™, DeviceNet™, Interbus and Profibus®-DP protocols, Micro 4000 NET allows instant access to all web guide functions (static centerline, oscillation, remote guide point adjust, manual mode, servo-center and automatic) and feedback ( edge detector error, actuator position, at in or out end-of-travel limit, at servo-center and in automatic mode).

Digital Speed and Accuracy — Automatically calibrates the web guide system for environmental changes, web process contaminents, and web edge changes every 4 milliseconds.

Operator Friendly — Intuitive touch pad interface with LED indicators. Setup parameters are located inside the controller, safe from inadvertent adjustments.

No Setup Downtime — The system performs continuous automatic calibration of edge detectors through AccuWeb’s exclusive dynamic compensation process.

Network Friendly — Optional fieldbus adapters easily interface with most popular fieldbus networks, including ControlNet™, DeviceNet™, Modbus Plus, Profibus®-DP, and Ethernet protocols. Discreet I/O interfacing is a standard feature.

Hazardous Duty — Optional provisions for use in Class I Division 1 hazardous environment. Note: control enclosure must be located outside of the hazardous environment.Reference UL certificates at www.ul.com.

Ratings — Enclosure is rated IP65 for protection from harsh environments, and designed to UL, EUL, CUL, CE and FCC codes.

Easy Installation — All components are contained within this single enclosure – reducing interconnections and easily installs on web guide equipment next to the web guide frame.